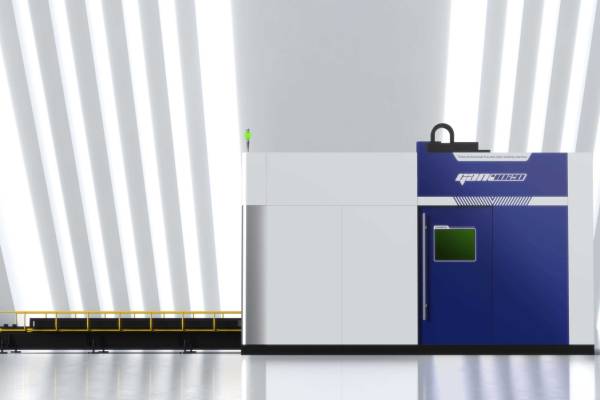

Dynotech is proud to collaborate closely with Penta Laser, a global leader in industrial laser technology, to deliver state-of-the-art laser metal cutting and welding solutions for a wide range of industrial applications.

Our partnership with Penta Laser enables us to offer advanced laser cutting equipment designed for sheet materials, with power ranges from 3KW to 60KW. These machines are available in multiple sizes, ensuring that we can meet the diverse processing needs of our clients, from precision cutting of thin sheets to high-power processing of thicker materials.

In addition to cutting, Dynotech also provides specialized metal welding and cleaning systems developed in collaboration with Penta Laser. These systems are engineered for robust performance, delivering precise and reliable metal joining and surface cleaning for industrial environments

Our systems can handle a wide range of metals, including stainless steel, carbon steel, aluminum, copper, brass, and nickel alloys, as well as some non-metals for specialized applications.

Laser cutting offers higher precision, faster processing speeds, minimal material waste, and cleaner edges compared to mechanical or thermal cutting techniques.

Laser welding delivers deeper, narrower welds with minimal distortion, higher speeds, and the ability to join complex or delicate components.

Yes, our laser solutions are designed for seamless integration with modern CNC systems and robotic automation for enhanced productivity and flexibility.

Depending on the power and configuration, our systems can process thin foils up to thick metal plates, with cutting capacities ranging from less than 1 mm to over 50 mm for certain materials.

Absolutely. Our machines are equipped with advanced safety features, enclosures, and interlocks to ensure safe operation in industrial environments.

Key industries include automotive, aerospace, electronics, heavy machinery, construction, and general metal fabrication.

We offer robust machine designs, preventive maintenance programs, and responsive technical support to maximize uptime and productivity.

Yes, our modular solutions are ideal for rapid prototyping as well as scalable for high-volume manufacturing with consistent quality.

Dynotech offers comprehensive training, process optimization, and ongoing technical support to ensure customers achieve the best results from their laser systems.

Copyright 2022 Dynotech. Designed & Developed By Conceptualise